Background

The first project I took on when I returned to Los ALamos was a project called ESRA. Part of the project was designing a collection of boards that could be used across different space missions. ESRA was supposed to be the predecessor for another mission called AIMSS. AIMSS would reuse these same boards for another instrument designed for the International Space Station.

I originally was not on AIMSS, however, the other embedded engineer who had done all the software for it left to go work for SpaceX about 2 months before we were to deliver the payload to NASA. I had to take over his entire workload in addition to mine and spent many many late nights trying to get the project working.

AIMSS included a total of five custom boards. Four of which became my responsibility. Because they were custom boards it takes many many hours of testing and troubleshooting to get them into a working state. Most my time shifted away from writing code to integrating these boards together and then again into the actual flight instrument.

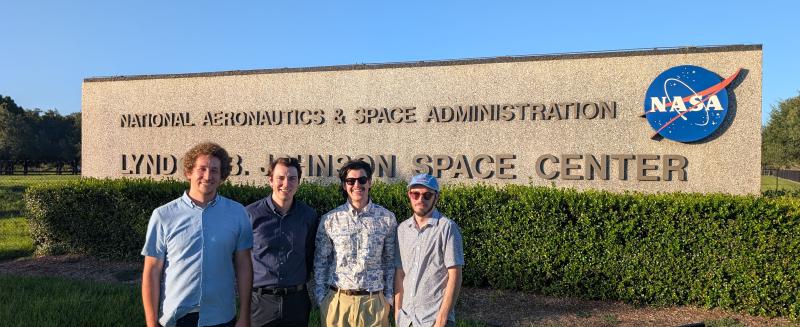

Eventually we had to deliver it. Because of my role in the integration of the payload, I was asked, along with one other guy, to drive it 14 hours to Houston to hand deliver it. After some more drama when putting the finishing touches on the payload, the delivery date got delayed another two weeks. It eventually ended up being four of us bubble wrapping the box, throwing it into the back of a government vehicle and hitting the road for a last minute delivery.

The integration of our payload was a pretty unique experience. Our “payload” was a box the size of a board game like Ticket to Ride and about 6 inches thick. We were told to bring our payload into a giant high-bay clean room in the NASA facilities where the rest of the payload was. After checking that our instrument was still alive we handed it over to STP (Space Test Program) to do their checkout before they bolted it into the rest of payload.

Unfortunately, we failed the requirements immediately. Some background: We had partnered with the United States Air Force Academy (USAFA) to build an interface board between our instrument and the STP electronics. Their board would be responsible for the electrical power and the communication to the space station. The person responsible for creating this board had left USAFA by the time we had delivered and there was no remaining help from the USAFA team. So when were told that the instrument was failing some electrical requirements we were on our own in Houston to fix it.

Long stroy short, we ended up having to literally take apart the entire thing and debug it there in Houston. It involved pouring over electronic schematic boards and photos to figure out where the problem is. Eventually after communicating with a team back at Los Alamos, we landed on a theory that the electrical problems stemmed from a revision that had been done to the board we were given, but that we could potentially overcome it by literally cutting a copper pathway embedded in the board. We found a technician who’d be willing to take a knife to our board. By some miracle that fixed the electrical problems.

The next day STP began bolting it alongside the rest of the instruments. Next began the software problems. Because we were relying on the USAFA board for comms we had assumed that they’d meet the requirements for communicating with STP. However, that turned out to not be the case. USAFA had given us a table indicating which bytes of a packet we could use that they would forward to STP and eventually to the ground. We had designed the instrument accordingly. However, the reality was that they used 4x as many bytes as they had told us, thus dropping our data, never transmitting it. This issue also eventually got resolved with some more reverse engineering of USAFA software.

All in all, AIMSS was delivered. It was a neat experience being in that high bay surrounded by NASA engineers. This was the very room that was used to build the command module of the Apollo mission that brought men to the moon. Here I was decades later troubleshooting problems to get my hardware into space.

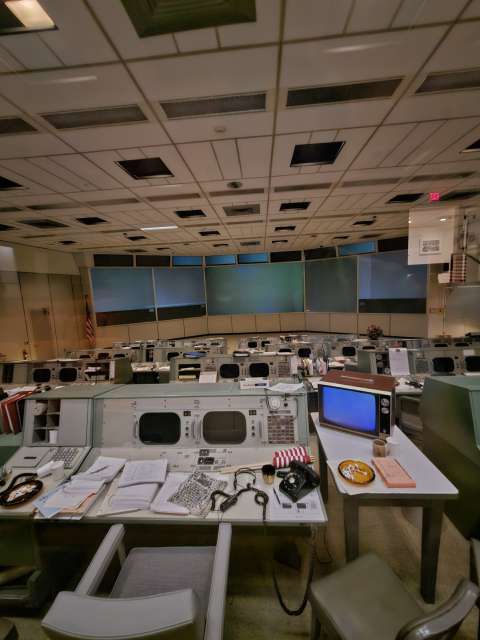

Once that was all finished, one of the STP engineers kindly gave us a tour of mission control where they orchestrated the moon landing, as well as the 1:1 mockup of the International Space Station used to train astronauts.

A very cool experience. Fingers crossed that AIMSS works as designed without any more of the drama. This will have been the fastest payload delivered by LANL for space since their very first satellite.